Polyurethane Timing Belt Manufacturers in India - Premier Belting

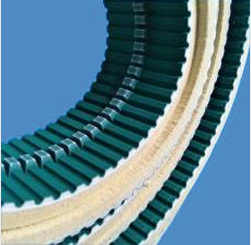

Premier Belting Solutions is higher-quality polyurethane timing belt manufacturers in India, where manufacturing operations require dependability produces. We are a leading heavy-duty industrial belts and components manufacturer, designed to operate under the most extreme conditions common to Indian industries. Our belts are constructed to deliver exceptional performance durability, providing extended service lives and substantial cost savings to your business.

Top Polyurethane Timing Belt Suppliers in India

Serve as well-known polyurethane timing belt suppliers in India. A tooth belt such as the bicycle chain for exact synchronism in a machine. It is constructed from polyurethane and is very resistant and provides high precision in power and motion transmission. Such belts are absolutely indispensable in those applications where exact timing and positioning are of supreme importance, for instance, in automatic assembly lines or robotics. We make different components of a machine move in absolute synchronism.

Types of Polyurethane Timing Belt:

Being as polyurethane timing belt manufacturers in India, it has different types as per stability purposes which are given below.

- Polyurethane Timing Belts with Specialty Coatings: Have specialty coatings (e.g., Linatex, PU foam, profiles) on teeth or rear to provide special material handling or grip opportunities.

- Polyurethane Timing Belts with Steel Cords: PU Timing Belts with steel tension members to provide increased tensile strength and dimensional stability for heavy-duty and precision applications.

- Black Rubber Timing Belt for Conveyor: It is made up of polyurethane but in mixture of black rubber that cause it different part in it.

- Rubber Industrial Timing Belt: Similar to the above, Mitsuboshi Timing Belts while it says "rubber," there are also industrial timing belts made of polyurethane.

- Open-Ended Polyurethane Timing Belts: Pre-cut and highly flexible to exact lengths, suitable for linear motion and where the belt is easier to replace with an open-ended style.

- Actually, Endless Polyurethane Timing Belts (Never Spliced): Splice-free design, for highest strength and even running, for heavy load and precision application.

- Fabric-Backed Polyurethane Timing Belts: Nylon cloth on tooth surface, with reduced wear, noise, and improved performance where high speed with low backlash is needed.

Technical Specification of Polyurethane Timing Belt:

We have added below a technical sheet of polyurethane timing belt in India that provides more technical information such as:

| Feature/Specification | Details |

|---|---|

| Belt Material | Thermoplastic Polyurethane (TPU) |

| Reinforcement Cords | High-Tensile Steel (standard), Kevlar, Stainless Steel, Carbon Fiber |

| Construction Types | Open-End, Truly Endless (seamless), Welded Endless |

| Common Applications | Precision Linear Motion, Robotics, Power Transmission, Synchronized Conveying |

| Typical Profiles | HTD, AT, T (Metric); L, H (Imperial) |

| Pitch Range | T5, T10, HTD 5M, 8M, etc. |

| Tensile Strength | Very High (500 N/cm - 10,000 N/cm+) |

| Operating Temp. | $-30^\circ$C to $+80^\circ$C (Standard) |

| Chemical Resistance | Excellent (oils, greases, ozone, hydrolysis) |

| Abrasion Resistance | Superior |

| Precision & Backlash | Very High Precision (Minimal Backlash) |

| Surface Mods. | Fabric Backing, Special Coatings (friction, antistatic) |

| Special Features | Antistatic, Food Grade, Clean Room Compatible, Low Noise |

| Customization | Profiles, widths, coatings, attachments |

| Industry Standards | ISO 5294/5296, FDA/EU (for food grade) |

Why Choose Polyurethane Timing Belt?

Select our polyurethane timing belts with previously unheard-of reliability and precision, designed by the finest technology for superior performance. Our application-matched products meet your heavy-industrial demands with maximum productivity and uptime. Our belts enjoy rigorous quality check and unmatched customer support for a seamless ride. Experience the difference of quality, innovation, and service that we deliver.

Features and Benefits of Polyurethane Timing Belt:

As leading polyurethane timing belt suppliers in India, it served different benefits in industries which as follow.

- Chemical and Oil Resistance: Polyurethane naturally resists most chemicals, greases, and oils, making it ideal for environments with severe exposure to these substances.

- Quiet and Clean Operation: Polyurethane belts run very quietly on chain drives, creating a cleaner working environment. They don't require lubrication, which prevents machine and product contamination.

- Enhanced Tensile Strength and Load Carrying Capacity: With steel or aramid tension members, polyurethane belts can carry tremendous loads. They offer high power transmission, suitable for heavy industrial applications.

- High Precision and Repeatability: Polyurethane belts maintain excellent dimensional stability and accurate tooth engagement. This ensures precise and correct synchronization of moving components, essential for CNC machines and robotics.

- Maximum Wear Resistance: The chemical composition of polyurethane provides superior wear and fatigue resistance, leading to a longer belt life even in harsh industrial conditions. This means less frequent replacements and lower overall maintenance costs.

Applications of Polyurethane Timing Belt:

As polyurethane timing belt manufacturers in India, it is applicable in different machinery and tools which as follow.

- Textile Industry Machinery: Used on spinning, knitting, and weaving machines for efficient processing of fibers and textiles. Their silent operation and purity are valuable in sensitive textile conditions.

- CNC Machines and Machine Tools: Central to precise location and synchronized motion of tools and workpieces. They enable precise machining of high quality and tight tolerance in production, crucial for complex designs and uniform product sizing.

- Packaging Machines: Facilitate stable synchronous motion for filling, capping, and labeling machines. The Black Rubber Timing Belt for Conveyor ensures a smooth, high-speed, and accurate packing process, reducing product wastage and improving packaging line efficiency.

- Robotics and Automation: Applied in accurate movement control of assembly robots and automated lines. They provide precision results from repeated motion with high production rates, essential for correct and frequent use in high-level automated machines.

- Material Handling Systems: Applied in product conveyor systems across most industries, such as logistics and packaging. Their stiffness withstands repeated use and a multitude of loads without stiffening.

Premier Belting Solution is the outstanding polyurethane timing belt manufacturers in India as well as outstanding polyurethane timing belt suppliers in India. Rubber Industrial Timing Belt the accuracy of motion precision by robots to material handling in heavy lifting, the belts are guaranteed, clean, and silent to operate and are now the answer to the reduction of cost of operation and increased output. Polyurethane timing belt technology offers a first-rate application to an industry-tested precise and rugged industrial process. Our improved dimension stability, chemical resistance, and wear resistance make them extremely valuable to the majority of industrial applications. Contact us today

FAQs:

A precision belt made of polyurethane, often with steel/Kevlar cords, featuring teeth that mesh with pulleys for slip-free, synchronous motion.

PU offers superior abrasion/chemical resistance, better dimensional stability (less stretch), cleaner operation, and usually longer life.

Generally -10°C to +80°C.

Ensure correct tension/alignment, regular inspection, cleanliness, avoid overloading, and prompt replacement of damaged belts.