PU Conveyor Belt Manufacturers in India - Premier Belting Solutions

Premier Belting Solutions is the leading PU conveyor belt manufacturers in India. We're a leading industry manufacturer, committed to driving industries around the nation with our durable, top-of-the-line solutions. Whether you need heavy machinery or agriculture, we get India's wheels rolling efficiently. opt for belt for dependability and efficiency that will last forever.

PU Conveyor Belt Suppliers in India

Being as outstanding PU conveyor belt suppliers in India. This is a conveyor belt that will move objects from one location to another, in our case, factories or warehouses. It's polyurethane (PU), which is hard plastic but flexible mixture. Because it's PU, it will be oil-resistant, grease-resistant, and wear-resistant too, that's why it will be appropriate for most industrial uses. It's a moving walkway for product, but of course, in a hard rubber-type compound, in a factory setting.

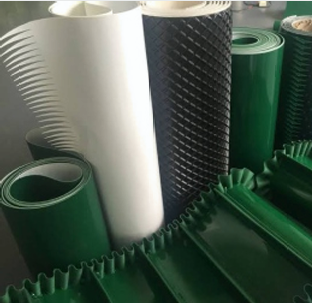

Types of PU Conveyor Belt:

Being as prominent PU conveyor belt manufacturers in India, it has different types so it is given below.

- Cleated PU Belts: These Polyurethane Conveyor Belt consist of more than one diversified profile or "cleats" developed on the surface and are utilized in preventing material reversal in conveying along slopes.

- Perforated PU Belts: Perforation-engineered or hole-shaped belts are sheathed in a linear way, which are used extensively in drainage, drying, or vacuum conveyance. These find our applications in food and drug processing. Perforated PU Belts.

- Timing PU Belts: Chewing into toothed or profiled sprockets at the bottom, timing belts offer accurate synchronism and high drive. It is a significant feature in automatic printing and assembly.

- Homogeneous PU Belts: Single-ply heavy-duty high-fidelity material belts. We possess adequate shock resistance and utilized in food processing because of easy cleaning from our sanitary state.

- Fabric Reinforced PU Belts: Since cast iron motorized PU conveyor belts fabric plies are utilized over the PU backing, these belts offer greater tensile strength as well as stability in dimensions. We possess greater ability to bear heavier loads as well as longer conveyor spans.

Technical Specification of PU Conveyor Belt:

We have added below a technical sheet of PU conveyor belt in India that provides more technical information such as:

| Feature/Specification | Details |

|---|---|

| Belt Material | Thermoplastic Polyurethane (TPU), often fabric-reinforced |

| Common Applications | Food Processing, Pharma, Logistics, Electronics |

| Available Types | Flat, Cleated, Sidewall, Profiled, Homogeneous |

| Typical Thickness | 0.5 mm - 10 mm+ |

| Tensile Strength | 2 N/mm - 15 N/mm (Working Load) |

| Operating Temp. | -20°C to +80°C (Standard) |

| Surface Properties | Smooth, Matte, Textured, Low Friction |

| Chemical/Oil Resistance | Superior (Excellent for oils, fats, cleaning agents) |

| Abrasion/Cut Resistance | Very High |

| Flexibility | High (Small pulley diameters, e.g., 4mm min.) |

| Hygienic Properties | Food Grade (FDA/EU compliant), Non-Porous, Easy to Clean |

| Special Features | Antistatic, Flame Retardant, Hydrolysis Resistant (Optional) |

| Joining Methods | Hot Vulcanized Finger Splice (preferred), Mechanical Fasteners |

| Industry Standards | FDA, EU 1935/2004, IS 1891 (Part IV) |

Benefits of PU Conveyor Belts

As PU conveyor belt suppliers in India, here are different benefits we provide which as follow.

- Greater Elasticity and Flexibility: Green Conveyor Belt the best balance of flexibility and elasticity to enable the belts to make circular journeys round tight bends and traverse tiny pulleys with minimum friction, hence lightening the stress on the conveyor system and achieving a saving in energy.

- Enhanced Abrasion Resistance: Due to PU Vertical Belt Conveyor its inherent wear and tear resistance to wear, PU conveyor belt manufacturers in India enhances the life of the belt by a very considerable margin. Replacement is less, and thus maintenance cost less.

- Enhanced Oil and Chemical Resistance: PU belts chemically withstand greases, oils, and industrial chemicals and hence are ideal for harsh industrial applications. It withstands them heavily against failure under any circumstance whether or not other chemicals touch the belt.

- High Hygienic Features: Since We are non-porous in surface finish and therefore smooth, we do not provide breeding ground for odor-causing bacteria and are easier in cleaning and with high-level hygiene demands. This is highly relevant in food processing, pharmacy, and cosmetics.

- Least Vibration and Noise: The fundamental characteristic of PU is less vibratory and noisy when under load than any other regular material. It improves the performance of the working condition and machine life.

Applications of PU Conveyor Belt

Serve as prominent PU conveyor belt manufacturers in India, it is applicable in different industries which are given below.

- Packaging and Logistics: Applied to Polyurethane Pu Belt Conveyor sort, divert, and transfer packages of any shape and size through warehousing and distribution centers. Strength is adequate enough to accommodate the high-capacity requirement.

- Fashion Textiles: Applied to convey materials, yarns, and clothes at various phases of production and finishing. PU Food Grade Belts have flat surface and will not leave impression on soft material.

- Automotive Manufacturing: Utilized in most assembly lines for conveying auto parts, components, and even auto bodies. We are strong and accurate and hence best suitable for efficient manufacturing process.

- Food Industry: White PU Conveyor Belt transport seafood to bakery food in a smooth and hygienic manner. Our non-toxic characteristics and hygienic makeup go very high in this sensitive process.

- Pharmaceutical Industry: During the transfer of pills, capsules, and packaging material, the PU belts have total controls over purity and control over contamination. We avoid product damage during the manufacturing stage.

Premier Belting Solutions is the well-known PU conveyor belt manufacturers in India as well as outstanding PU conveyor belt suppliers in India, A purchasing order for a product of PU conveyor belts is a purchasing order of increased productivity in manufacturing, reduced maintenance, and better-quality product for virtually all industry. We have smooth running and longer lifespan like cosmic cost savings and uptimes for your manufacturing operations. Mild Steel Chain Industrial Conveyor Belts are fast replacing all the other conveyor belts as the preferred option for virtually all applications. Use PU conveyor belts as We have unmatched abrasion resistance, chemical, and oil resistance as well as greater level of hygiene features.

FAQs:

A conveyor belt made from polyurethane, offering durability and flexibility.

Proper tensioning, tracking, regular cleaning, system inspection, and correct storage.

Yes, often with patterned surfaces or cleats for grip.

Yes, due to their smooth, non-porous surface.

Minor damage sometimes, but replacement is often best for significant issues.